Improving Prototype Design: The Use of 3D Models

Introduction

In our rapidly advancing technological world, innovations are fostering unprecedented growth and development. In the realm of product design, one incredible innovation notably stands out, and that is the use of 3D models in prototype design. This invaluable tool is remarkably enhancing the traditional prototype process, increasing both efficiency and effectiveness.

The Value of Prototypes in Product Design

Creating a prototype is an integral stage in product design, offering a tangible object that represents an abstract concept. These models allow for exhaustive testing of functionality, aesthetics, and overall consumer acceptance before making any substantial manufacturing investments. With traditional methods being both time and resource-intensive, the rise of 3D modeling has instantly proven invaluable. It provides a streamlined, cost-effective, and efficient method for enhancing prototype design.

Why Use 3D Models?

Looking closely at the benefits, there are several reasons to incorporate 3D models into your prototype design process.

- Enhanced Visualization: Traditional methods provide two-dimensional representations, which can lack depth and detail. 3D models, however, breathe life into these representations, fostering an in-depth understanding of the prospective product.

- Efficiency: The process of designing, prototyping, and testing can be lengthy when relying on traditional methods. With 3D modeling, the timeline for creating accurate, detailed prototypes is significantly reduced.

- Precision: With 3D models, minute details of the prototype can be thoroughly evaluated, resulting in a highly accurate representation of the final product.

- Cost-Effectiveness: Because 3D modeling primarily requires software, it eliminates the need for extensive physical materials and substantially reduces labor costs.

How are 3D Models Enhancing Prototypes?

Beyond the undeniable benefits, examining how 3D models hold the power to improve prototypes is just as crucial.

- Improved Design Flexibility: The ability to modify designs dynamically based on immediate insights and feedback is invaluable. It can profoundly reduce the risk of design flaws and enable more flexible iterations.

- Real-Time Testing: With 3D printing technology, a tangible product can be held and tested by users, enabling real-world testing and accelerating improvements through instant feedback.

- Collaboration: 3D models, being easily shareable, encourage collaboration among designers, engineers, marketers, and even end-users, providing a more holistic and well-rounded prototype..

3D Modeling: A Success Story

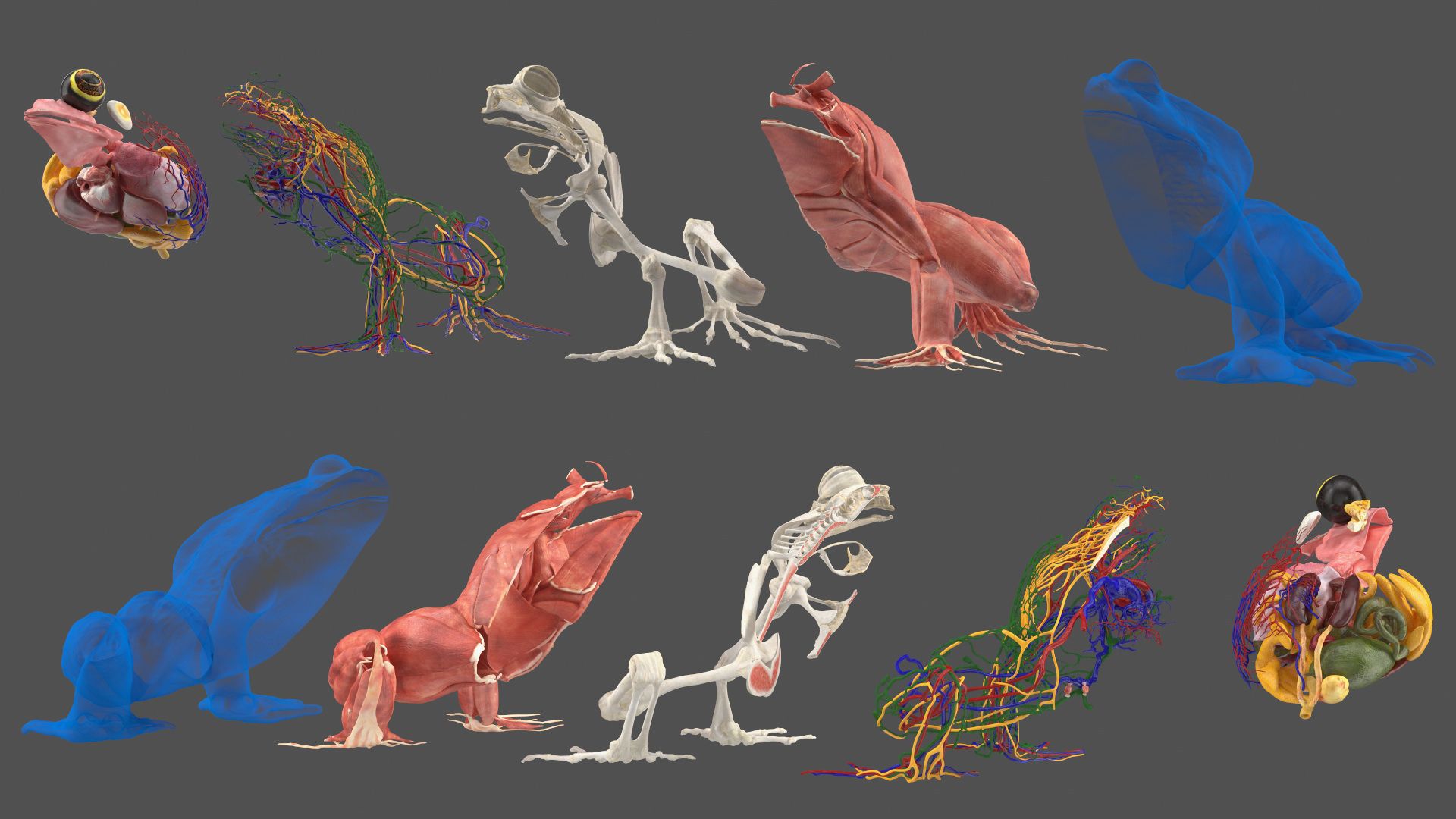

The biomedical field has astoundingly adopted 3D models, using them to create highly accurate prototypes of medical equipment. Beyond that, the future holds promising advancements in bioprinting, where 3D modeling will enable the printing of complex human tissues and organs.

Conclusion

The arrival of 3D models as a prototyping tool marks an exciting frontier in design improvements. As this technology continues to evolve and adapt, we can expect even more streamlined design processes, improving the quality of final products while reducing both the costs and the resources required.

This incredible design leap ensures a future where imagination and innovation are the only limits. We are privileged to be a part of this journey, as we witness the intersection of creativity and technology, redefining the possibilities of prototype design.