How to Select the Perfect Material for Your 3D Print

Welcome to the innovative world of 3D printing, a realm where blueprints transform into tangible models and wild ideas morph into reality. An integral part of this process lies in understanding how to select the perfect material for your 3D print. From PLA, ABS, Nylon, Resin to exotic wood and metal filaments, the choice is vast and certainly daunting for beginners. Picking the right material can significantly impact the functionality, appearance, and overall success of your 3D printing project.

Establish the Intention

Identify the purpose of your 3D print. Is it a prototype, a functional part, or a decorative piece? Will it be subjected to heat, moisture, or mechanical stress? Is flexibility needed or rigidity preferred? Answers to such questions help narrow down the material selection and cater to specific requirements.

- Prototypes and Models: For prototypes, PLA or ABS make excellent choices. They print well, sand easily, and offer optimum dimensional accuracy.

- Functional or Mechanical Parts: These often require durable and heat-resistant materials. Thus, ABS, PETG, or Nylon should be considered.

- Decorative Pieces: For decoratives or display items where aesthetics override functionality, Wood or Metal-filled filaments offer unique textures and finishes.

Understand Material Characteristics

Familiarize yourself with the properties of different 3D printing materials to make an informed choice:

- PLA (PolyLactic Acid): PLA is the most commonly used material in 3D printing, loved for its ease of printing, minimal warping, and availability in various colors. However, it’s not suitable for heat exposure or mechanical stress.

- ABS (Acrylonitrile Butadiene Styrene): ABS is trusted for its durability, heat-resistance, and higher flexibility than PLA. Yet, it’s more prone to warping and difficult to print.

- PETG (Polyethylene Terephthalate Glycol): PETG offers the best of both worlds from PLA and ABS, providing ease of printing, decent strength, and good heat resistance.

- Nylon: Renowned for its flexibility, longevity, and chemical resistance. However, it tends to absorb moisture and needs a controlled environment to print well.

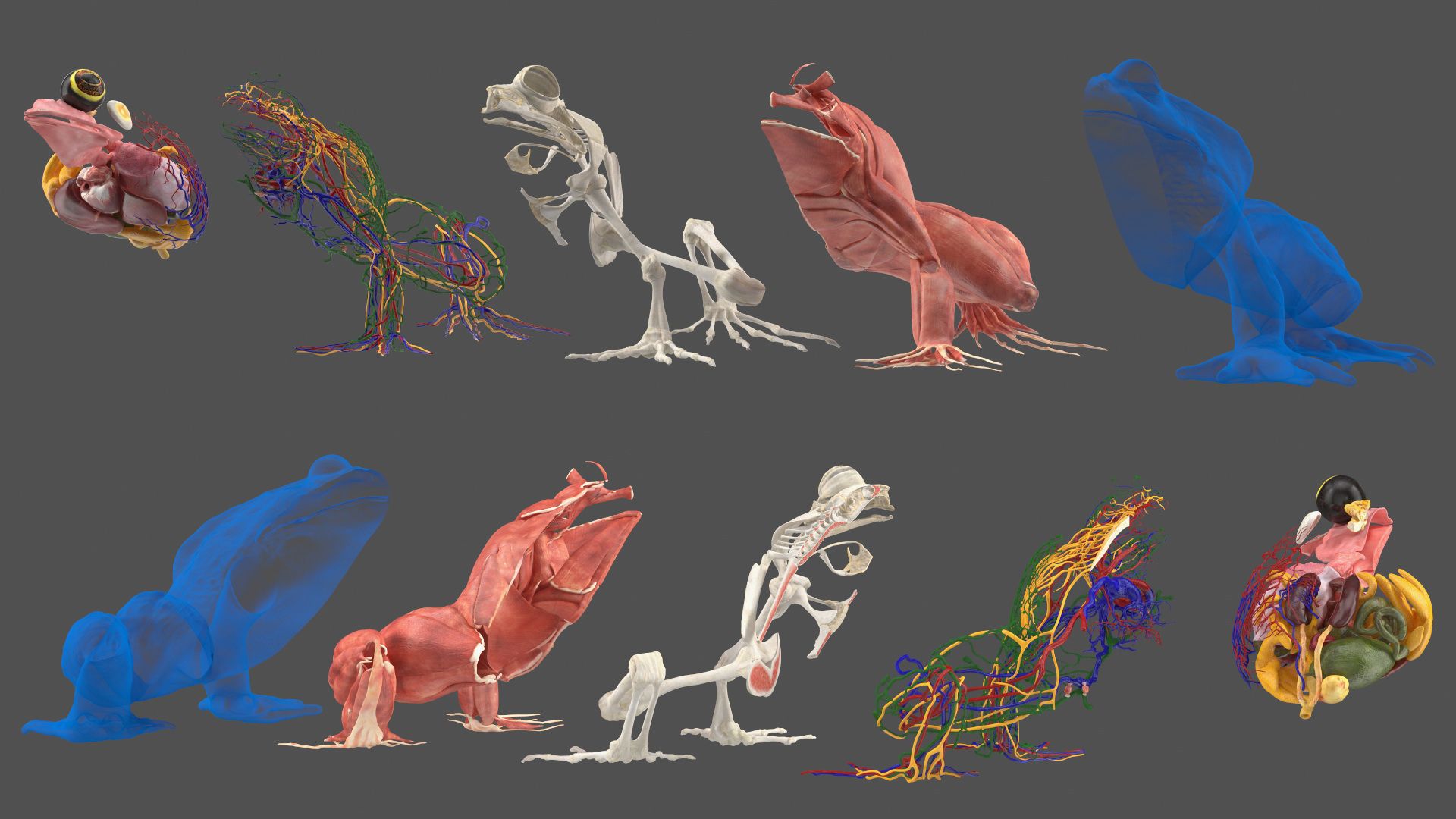

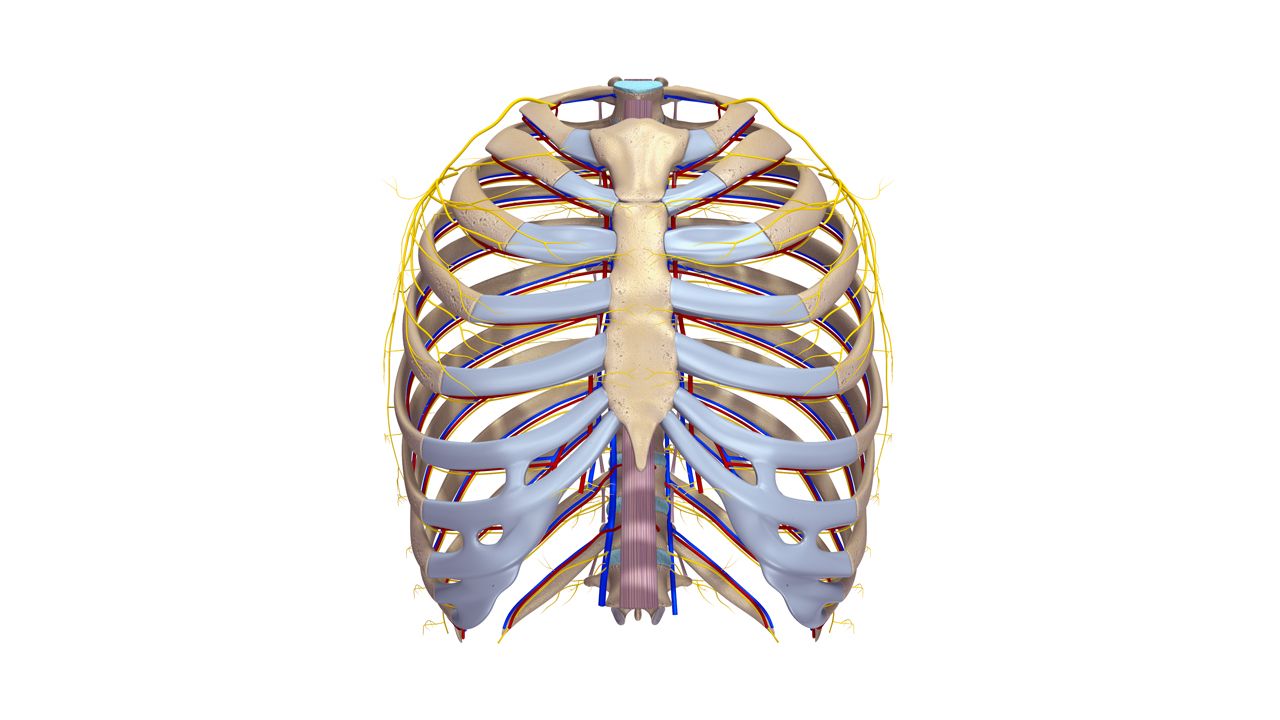

- Resin: Resin printing offers extraordinarily high detail, making it perfect for miniatures and models that require intricate details.

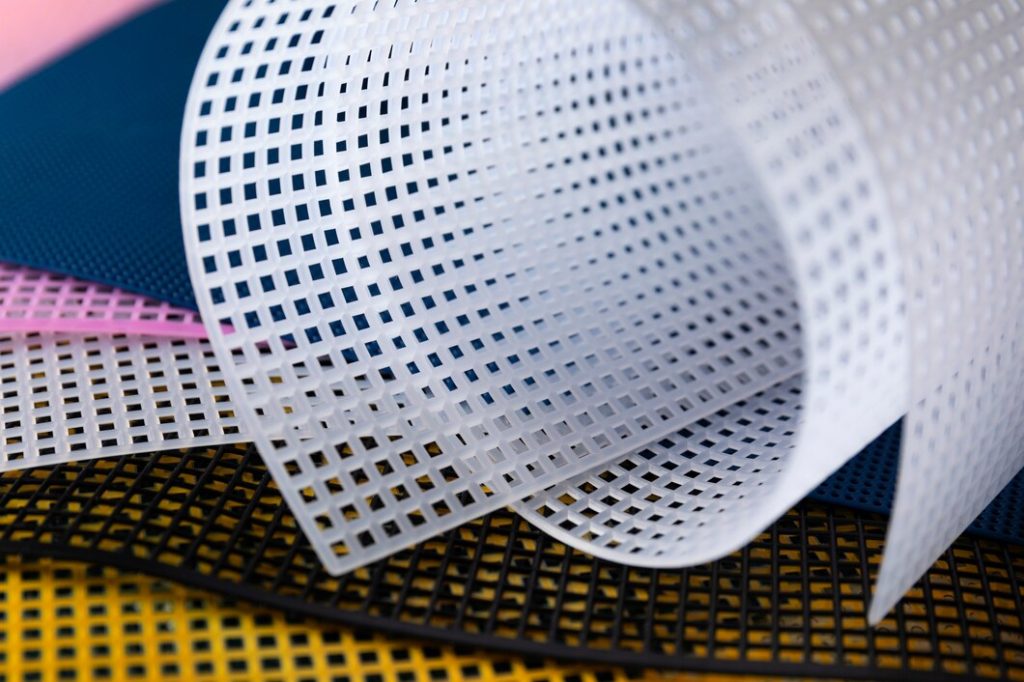

- Special Filaments: Wood, Metal-filled, Carbon Fiber-infused filaments offer unique properties and finishes but require good 3D printing experience.

Consider your 3D Printer’s Capabilities

Not all printers can handle every material. Lower-end printers primarily handle PLA and, to some extent, ABS. In contrast, advanced printers with heated print beds, enclosed chambers, and high-temperature extruders can manage more challenging materials like Nylon or Carbon Fiber-infused filaments.

Material Cost

Your budget plays a crucial role. Basic filaments like PLA and ABS are cost-effective, while specialty filaments and industrial-grade materials are pricey.

Environmental Impact

If sustainability matters to you, consider environmentally friendly materials. PLA is biodegradable, and recycled filaments are also growing in popularity.

Choosing the ideal material for your 3D print can be a game of trade-offs between functionality, aesthetic needs, printer compatibility, cost, and environmental sustainability. Try out different materials and learn from experimentation, as this process fuels the journey of mastering 3D printing. There’s no one-size-fits-all answer; instead, every 3D printing project provides an opportunity to explore the dynamic material landscape, propelling you closer to the perfect print.