How to Improve Your Design Process Using a 3D Scanner

In an era where technology and innovation are propelling industries forward, embracing tools that enhance efficiency and precision is fundamentally important. One such tool that is changing the game is the 3D scanner. Offering speed, accuracy, and flexibility, 3D scanners can remarkably enhance the design process. This guide aims to illuminate how to effectively incorporate 3D scanners into your design framework and reap their impressive benefits.

1. Getting To Know 3D Scanners:

Before embarking on the journey of using a 3D scanner, understanding what it is and how it functions can be beneficial. In essence, a 3D scanner captures the physical world around us, converting objects into digital 3D models. They operate by projecting light onto an object and using a camera to record the distance and shape of that object.

2. Choosing The Right 3D Scanner:

There are a plethora of 3D scanners in the market, each designed with different principles, accuracy, range, and cost. From portable handheld scanners to high-resolution stationary ones, selecting a scanner that aligns with your project’s requirements and budget is vital.

3. Incorporating 3D Scanning In Your Design Process:

Here are the key areas where a 3D scanner can boost your design process:

Design Capturing and Replication:

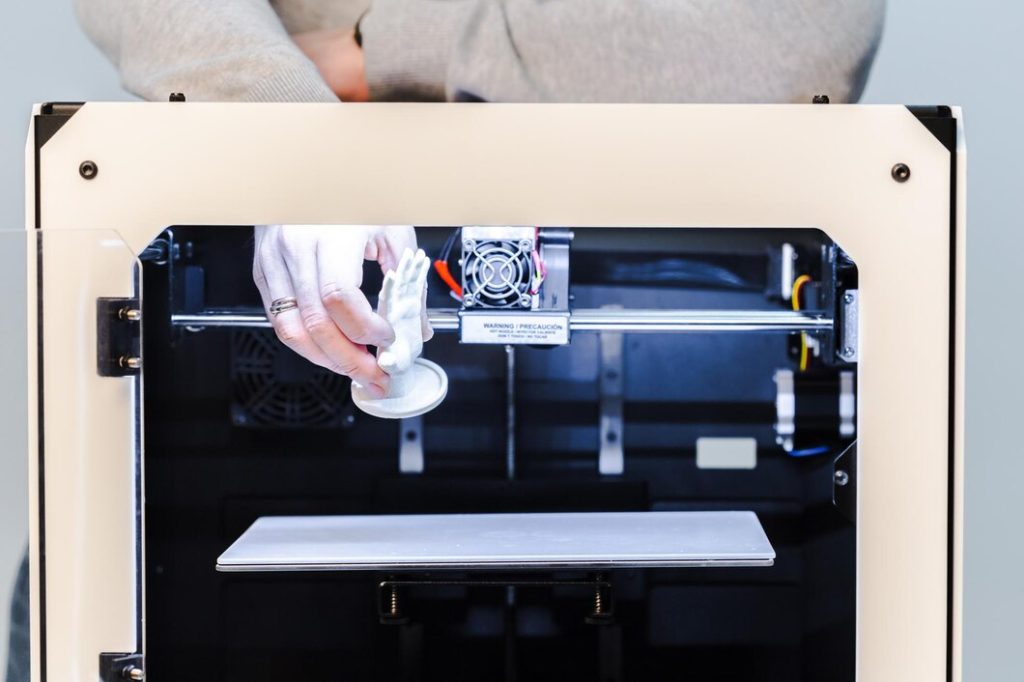

3D scanners can accurately capture the design of an existing object. This function is particularly useful when replicating or modifying an existing design. The scanned object can be imported into a CAD program for further design modifications.

Quality Control:

3D scanners can quickly identify discrepancies between initial designs and final products, allowing for prompt rectifications. Regular scanning during the process can ensure high standards of quality control.

Reverse Engineering:

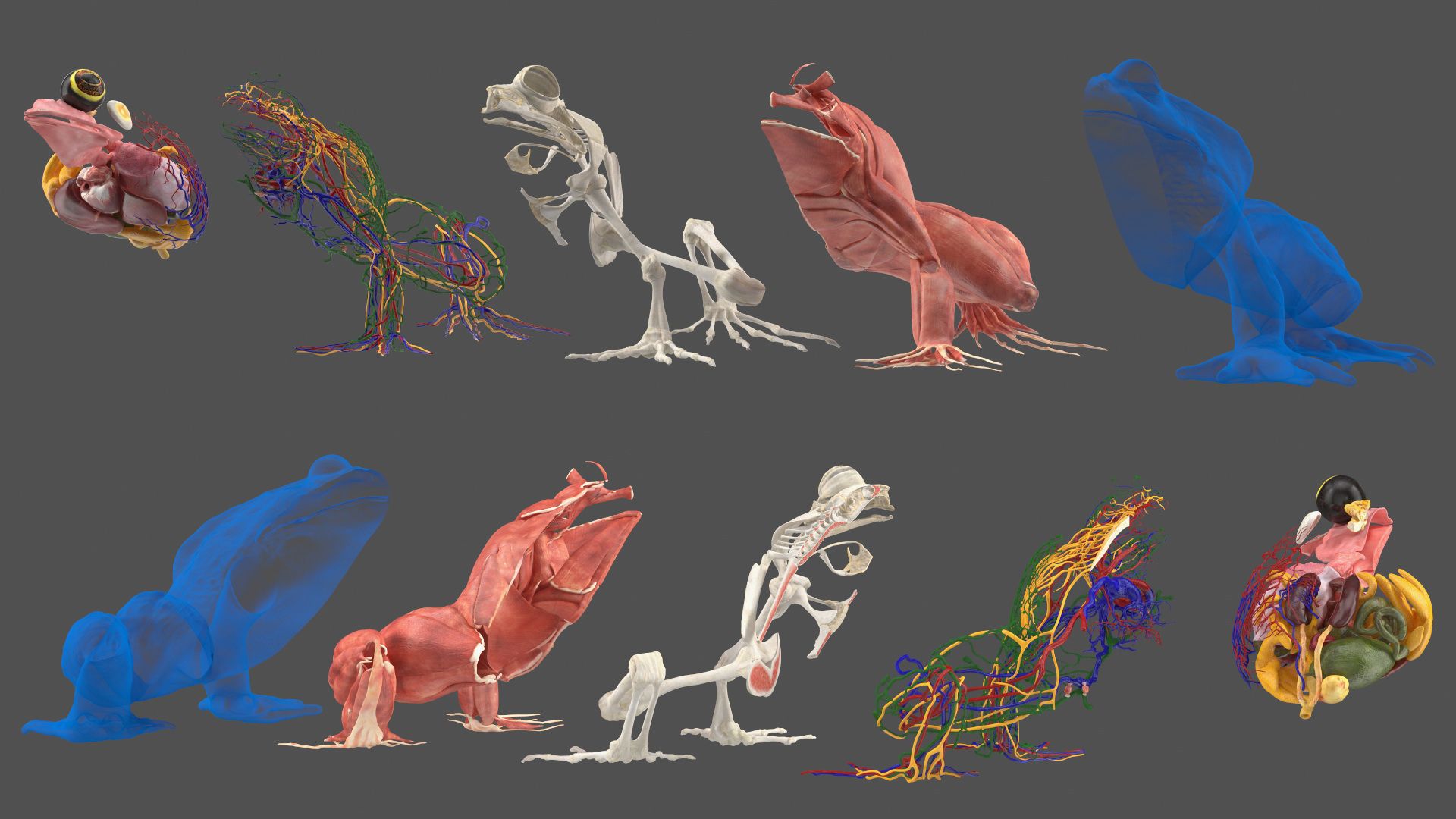

Understanding the design of a product without knowing its underlying construction can be a daunting task. 3D scanners can break down an object into simpler sub-components digitally, enabling a deeper understanding of its design and function.

Prototype Testing and Refinement:

Before mass production, a prototype undergoes multiple rounds of testing and refinement. A 3D scanner allows swift modifications to the design based on testing results, accelerating the process.

4. Utilizing 3D Scanners Efficiently:

To maximize the benefits of 3D scanners, focusing on correct usage and regular maintenance is critical. Proper training and familiarization with the equipment will help prevent errors and ensure consistent accuracy.

5. Keeping an Eye on Emerging Trends:

The 3D scanning technology is continually advancing, with newer models offering higher resolution, speed, and software compatibility. Keeping pace with these trends can keep you ahead of the curve and enable efficient adaptation to advancements.

Conclusion:

Incorporating a 3D scanner into your design process can revolutionize your design approach and significantly improve efficiency, accuracy, and speed. While the technology might seem intimidating initially, the value it adds to the design process makes it an investment worth considering. As we propel into a more digitized and technologically advanced era, acclimating to tools like 3D scanners can empower our capacity to create, design, and innovate more effectively.

This is the best post I have read, when most other bloggers writing about this won’t stray from the scripted opinion. You have a great writing style, and I shall check back as I get a lot from your writing.

I really appreciate your help

Thank you for your articles. They are very helpful to me. May I ask you a question?

I really appreciate your help