How to Enhance Product Design with 3D Models

Embracing technology is a surefire way to gain a competitive edge in today’s market, and the product design industry is no exception. The advent of 3D modeling has revolutionized the way products are designed, turning the impossible into reality, and elevating creativity to unforeseen heights. Here, we elaborate on how to enhance product design using the power of 3D models.

Rapid Prototyping:

Time is a commodity that businesses cannot afford to waste. Creating physical prototypes is often a time-consuming process. With 3D modeling, however, you can swiftly create and refine an exact digital replica of your product, saving crucial time and resources. You can identify changes needed early in the design process, paving a smooth path from concept to market.

Precise Designs:

3D models provide an avenue to design precision that is almost unparalleled. They allow designers to create, analyze, and fine-tune every minute detail of a product. This enhanced precision means that product designs are accurate to scale, eliminating room for error and greatly reducing the risk of costly mistakes in the production phase.

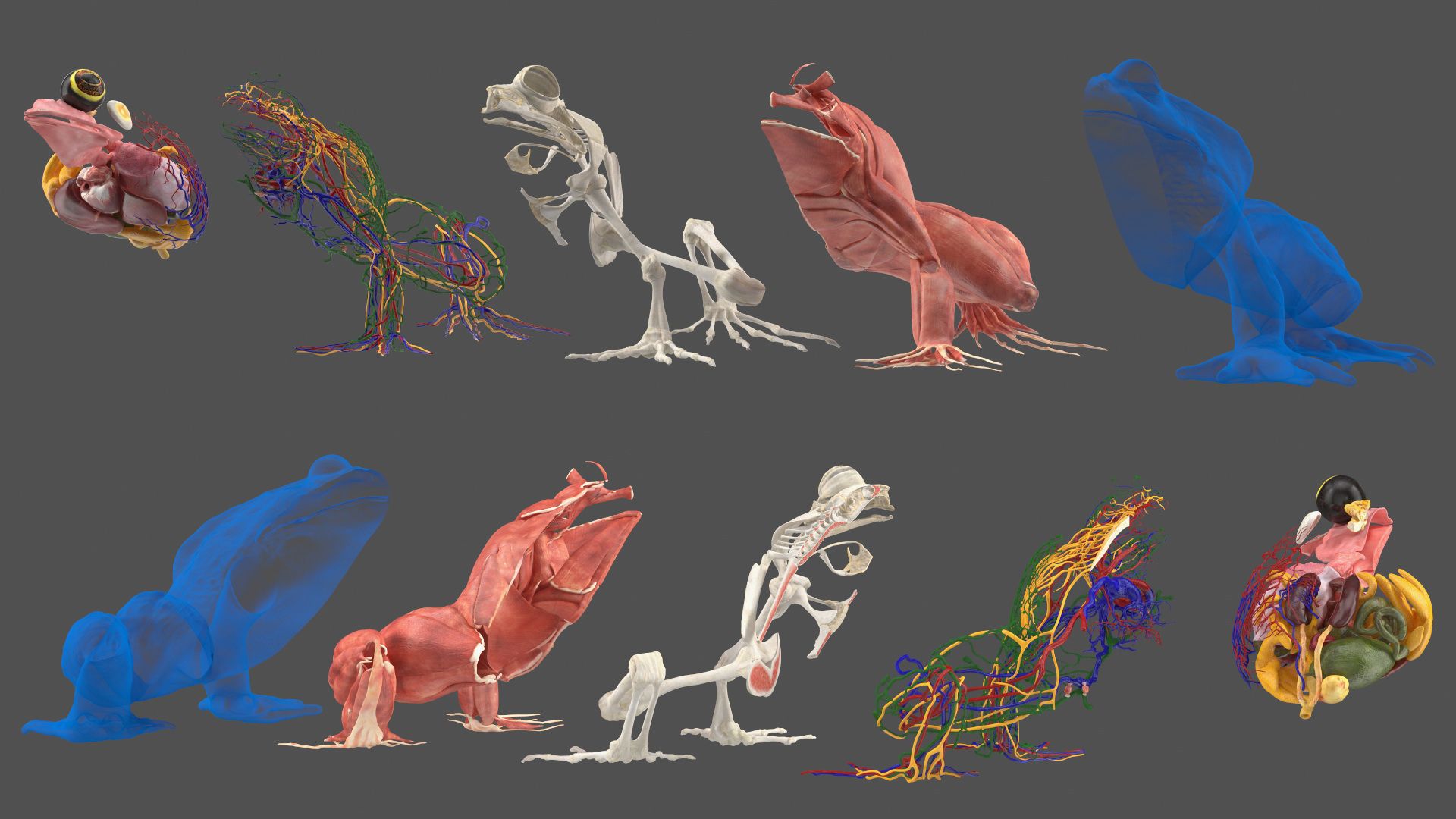

Improved Visualization:

One of the foremost advantages of using 3D models in product design is the enhanced level of visualization it provides. 3D models offer a physical sense of a product before it is manufactured, providing a realistic feel from every angle. This can be particularly beneficial when presenting a new product concept to stakeholders or clients who can visualize the final product more comprehensively.

Advanced Testing:

With a 3D model, it becomes possible to conduct advanced testing procedures that might not be feasible with traditional 2D designs or physical prototypes. For instance, different aspects of a product such as its durability, performance under stress, or its aerodynamics can be tested using sophisticated 3D modeling software. This helps designers identify and rectify potential flaws before the production stage.

Customization:

In an age where personalization holds paramount importance, 3D models prove indispensable. Once a model has been created, it can readily be customized to fit different variations. This means that businesses can cater to a wider range of customers, offering products tailored specifically to their requirements.

Cost-Effective Modifications:

In traditional product design, any change, however minor, would often require a completely new prototype. But with 3D models, designs can be easily altered digitally at virtually no cost. This flexibility in design alteration immensely reduces both the cost and time spent on developing new prototypes.

Eco-friendly Design Process:

The switch to digital can significantly reduce the carbon footprint associated with product design. 3D modeling eliminates the need for creating multiple physical prototypes, thus saving materials and leading towards an eco-friendly design process.

One must note, however, the process of 3D modeling requires designers to acquire certain technical skills. The initial learning curve can appear daunting. However, with abundant online resources and courses available, this hurdle can be overcome.

As technology, market trends, and customer expectations continue to evolve, businesses must remain flexible and adaptable. In leveraging 3D models in product design, you stand to reap benefits that bolster time and cost-efficiency, design precision, and customer satisfaction.

Therefore, incorporating 3D modeling into your design process may just be the game changer your business needs. It’s no longer just about keeping pace with the digital era; it’s about innovating and leading the way. As the world spins further into the realm of 3D, there is no better time than now to step into this exciting dimension.